Discover How a Membrane Switch Boosts Toughness and Capability in Instruments

How Membrane Layer Changes Contribute to the Toughness of Electronic Control Panels

Membrane layer switches play a vital duty in enhancing the sturdiness of electronic control panels, primarily with their multi-layered building which gives efficient security versus ecological factors such as dampness and dust. The absence of relocating components dramatically minimizes the chance of mechanical failings, making membrane layer switches suitable for requiring applications.

Definition of Membrane Layer Buttons

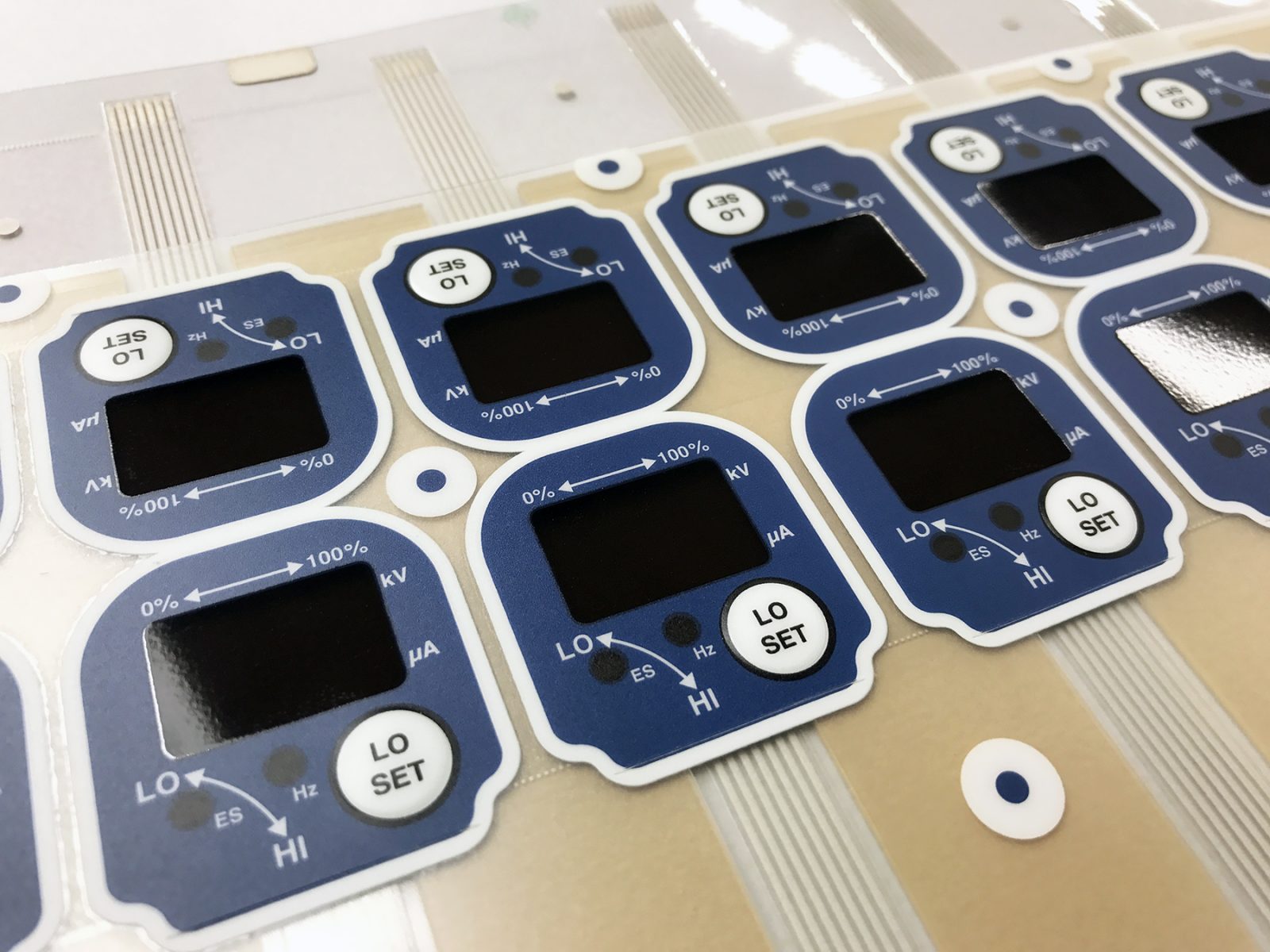

Membrane layer buttons are created to be thin and lightweight, making them ideal for applications where space is restricted. They can be made in various shapes, dimensions, and colors, supplying flexibility in layout that meets aesthetic and functional needs. In addition, membrane layer switches can include different modern technologies, such as tactile responses and LED indications, improving user experience.

Due to their building and construction, membrane switches are typically immune to dust, moisture, and general wear, adding to their durability sought after atmospheres. Their seamless layout not just promotes easy cleaning yet also minimizes the risk of mechanical failing, making them a preferred selection for suppliers looking for trustworthy individual interfaces in their electronic control board.

Security Versus Ecological Elements

The layout of membrane switches inherently offers a degree of protection against different ecological aspects, which is important for keeping functionality in challenging problems - Membrane Switch. These switches are generally constructed with layers of adaptable materials that secure inner components from moisture, dirt, and pollutants. By encapsulating the wiring, membrane layer changes reduce the threat of short circuits and corrosion, which can dramatically impair efficiency

Moreover, making use of durable adhesives and sealers throughout manufacturing enhances their resistance to environmental difficulties. Membrane buttons can sustain direct exposure to chemicals and solvents, making them appropriate for industries such as food handling and medical care, where health and cleanliness are critical. Their smooth surface area design additionally avoids the buildup of dirt and microorganisms, assisting in less complicated cleansing and upkeep.

Temperature changes are one more environmental concern, and membrane layer switches are crafted to function efficiently across a wide variety of temperatures (Membrane Switch). This versatility guarantees that control board stay functional in different setups, from industrial settings to customer electronics

Influence On Customer Interaction

User communication with digital control board is significantly influenced by the design and capability of membrane buttons. These switches offer a tactile user interface that improves the general individual experience, allowing for instinctive navigation and control. Their responsive nature ensures that customers obtain prompt feedback upon activation, which is critical for jobs needing accuracy and efficiency.

Additionally, the smooth surface area of membrane switches helps with very easy cleaning and maintenance, promoting customer confidence in the dependability of the user interface. This tidiness is specifically essential in atmospheres where hygiene is straight from the source critical, such as medical or food processing setups. Furthermore, the small and light-weight design of membrane changes adds to the aesthetic allure of control panels, urging user involvement via a modern-day and smooth look.

Furthermore, the combination of aesthetic components, such as printed symbols and backlighting, aids customers promptly identify features, decreasing the discovering curve linked with brand-new tools. As an outcome, customers can run gadgets much more efficiently, resulting in raised efficiency and fulfillment. In recap, membrane layer switches play a pivotal function in improving individual communication by combining functionality, aesthetics, and convenience of usage, eventually leading to boosted operational efficiency.

Style Versatility and Personalization

Style flexibility and modification are vital elements of membrane buttons, making it possible for producers to customize electronic control board to particular applications and individual requirements. This flexibility enables the combination of various layout aspects, such as shades, graphics, and appearances, which can enhance the aesthetic allure and individual engagement of the control board.

Membrane switches can be customized in shapes and size, accommodating a variety of devices and applications, from industrial equipment to consumer electronics. This versatility makes certain that manufacturers can create intuitive interfaces that line up with customer expectations and operational needs. Furthermore, the ability to integrate distinct functions such as backlighting or responsive comments additionally improves use, allowing for a more interactive experience.

Furthermore, the manufacturing procedure for membrane changes supports the quick prototyping of styles, allowing makers to iterate and refine their ideas quickly. This capability not just speeds up the development timeline however likewise makes sure that the final item meets certain practical and visual criteria.

Cost-Effectiveness and Longevity

Cost-effectiveness and durability are significant advantages of membrane switches, making them an appealing alternative for suppliers and end-users alike. These buttons are commonly less pricey to generate than typical mechanical switches, mostly as a result of their streamlined production processes and the lowered number of components called for. This cost benefit expands not only to preliminary manufacturing however also to lasting operational expenditures, as membrane layer buttons frequently require much less upkeep and have a reduced failing price.

Additionally, the durability of membrane layer switches over contributes to their total worth. Built from long lasting materials, they are immune to environmental variables such as moisture, dust, and chemicals, which can lead to early wear in other switch kinds. The lack of relocating components reduces mechanical failing, enabling membrane layer switches to preserve capability over extended periods.

This sturdiness is particularly useful in applications requiring regular efficiency under requiring conditions, such as clinical tools and commercial equipment. Ultimately, the mix of cost-effectiveness and longevity makes membrane layer basics switches a financially sensible choice for producers, offering reliable services that hold up against the examination of time while optimizing monetary considerations.

Conclusion

In final thought, find more membrane layer switches significantly improve the resilience of electronic control panels through their robust construction and safety features - Membrane Switch. Generally, membrane layer switches stand for a trusted and cost-efficient choice for boosting the longevity and capability of electronic control systems.